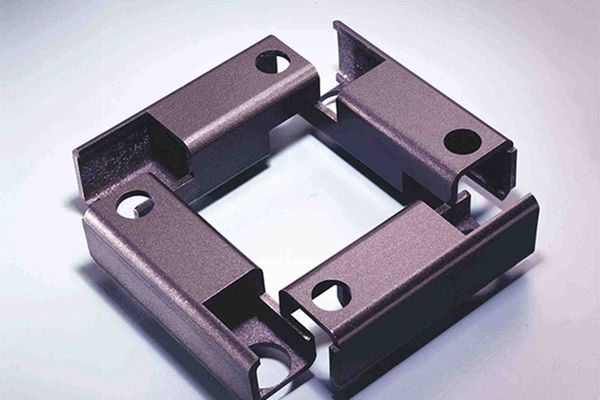

Modern electronic devices require components that combine functionality, strength and design . Approximately 20-30% of the parts in these devices are produced using metal stamping techniques. At MFS , we develop advanced solutions for manufacturing housings and connectors that ensure the durability and proper functioning of products such as phones, computers and televisions.

Challenges in the electronics industry

Constant technological innovation requires manufacturing processes that can quickly adapt to new market demands. Precision in electronic parts is essential to ensure device compatibility and performance. In addition, manufacturers must balance quality with cost and production time optimization.

Our solutions

Why choose MFS?

By choosing MFS, you get parts that meet the highest standards of precision and durability, allowing you to offer reliable and competitive products in the market. Our technology helps reduce production times and optimize the use of materials, generating significant savings for your company.

Common Applications

- Cases: Metal structures to protect devices such as computers, televisions and smartphones.

- Connectors: Terminals and essential components that guarantee the connectivity and proper functioning of the equipment.

Ready to optimize your processes?

Contact us and we will take your forming processes to the next level